TQM

|

"pdponline" TQM |

|

| TQM | TPM | | | Contact | |

| TOTAL PRODUCTIVE

MAINTENANCE Historical Background of TPM concept Till 1950s organisations were carrying out breakdown maintenance. As and when a machinery goes out of order maintenance crew will attend to that and put it back to normalcy for production. In 1950s in USA 'Preventive Maintenance' system was introduced. Under this either during the holidays or taking planned shutdown machineries were checked for their wear and tear. Necessary actions like, timely change of worn-out parts, repair etc., were carried out. Leaving that major cleaning operations, oiling, checkup of the set up, alignment etc., were done. Preventive maintenance helped to create an awareness and recognition about the importance of reliability and economic efficiency in plant design etc. In 1960s the 'Productive Maintenance' came into existence. Awareness created a system of regular check on a day to day basis like checking up the tightness of the nuts, bolts, leakages etc. This caused 'Maintainability Improvement'. Preventive maintenance and maintainability improvement helps to bring 'Maintenance Prevention' i.e., considerable reduction in maintenance activities. Japan adopted Preventive maintenance and Productivity maintenance in their plants. Seiichi Nakajima in 1971 made Productive Maintenance as Total Productive Maintenance. If quality can be responsibilities of the process control people, why not the machine they use also? He created a comprehensive system wherein autonomous maintenance became an integral part of productive maintenance system. TPM is achieving PM efficiencies through comprehensive system based on respect for individuals and total employee participation and it brought in autonomous maintenance in to the system. Definition of Total Productive Maintenance 1. To set a goal to maximise

equipment efficiencies (overall efficiency). How TPM work is done? TPM is carried out by all employees through small group activities like Quality Circle and is part of TQM. Like quality control activities carried out company wide TPM is equipment maintenance performed on a company wide basis. What said above makes it clear that TPM is not an activity restricted to production area. It is now a new direction in production. Modern tough competition has brought in automation and robotization. Now not only Quality but also products cost, inventory, safety, health etc., are dependent on equipment. But they are not going to do away with human labour completely. Only output can be automated, maintenance still depends upon human being. TPM has now dual goal - Zero breakdown. This has brought in the new definition for TPM. New definition for TPM 1. Taking a prime objective a

company structure that pursues production efficiency to its ultimate

limits (= comprehensive efficiency). Benefits of TPM It is found to be benefiting in all areas Productivity:

Increases * Labour productivity. Reduces * Breakdown. Quality: Reduces * Defects in in-process

material. Cost: Reduction

in * man power. Delivery: Reduced stock (by

days). Safety: Zero accidents. Morale: Increase in improvement ideas

submitted. Now let us see to institutionalise TPM in an organisation what kind of an organisational set up needed and what kind of losses it prevents or reduces and how to train the people for autonomous maintenance etc. TPM Development Programmes There are four stages and twelve steps involved in this. STAGE A: PRELIMINARY STAGE STEP 1 Announcement by Management to all about TPM introduction in the organisation. Like for any concept proper understanding, commitment and active involvement of the top management in needed for this also. Senior management should have an awareness programmes prior to this and also frank discussion amongst themselves and a firm decision based on that. Once decided announce it to all. Publish it in the house magazine and put it in the notice board. Send a letter to all individuals if possible. STEP 2 Initial education and propaganda for TPM. Training is to be done based on the need. Some need intensive training and some just an awareness. Take people who matters to places where TPM already successfully implemented. STEP 3 Setting up TPM and

departmental committees. TPM includes improvement,

autonomous maintenance, quality maintenance etc., as part of it. When

committees are set up it should take care of all those needs.

STEP 4 Establishing the TPM working system and target. Now each area should benchmark and fix up a target for achievement. STEP 5 A master plan for institutionalising. Our next step is implementation

leading to institutionalising wherein TPM becomes an organisational

culture. Achieving PM award is the proof of reaching a satisfactory level.

Do not forget award is not ultimate, as there is no limit for

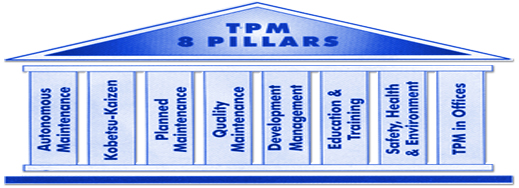

improvement. STEP B - INTRODUCTION STAGE STEP 6 Kick off or starting of TPM This is a ceremony and we should invite all. Suppliers as they should know that we want quality supply from them. Related companies and affiliated companies who can be our customers, sisters concerns etc. Some may learn from us and some can help us and customers will get the communication from us that we care for quality output. STAGE C - IMPLEMENTATION In this stage eight activities

are carried which are called eight pillars in the development of TPM

activity. STEP 7 Establishing

systems for improving production efficiency 7.1 Individual improvement for

manufacturing equipment efficiency thereby maximisation of production

efficiency and reduction of losses. STEP 8 Establishing

initial control system for new product and

equipments Production engineering department must design a maintenance free equipment at the design stage and product engineering department must stabilise the operation of new equipment at the earliest. STEP 9 Establishing a Quality Maintenance set up. This is setting conditions without defectives and its maintenance and control. STEP 10 Establishing systems to improve. Efficiency improvement of

administration and other indirect departments. STEP 11 Establishing a safety and environment management plan. Establishing zero accidents and zero pollution system. Getting certified under ISO 14001 standards. STAGE D - INSTITUTIONALISING STAGE By all there activities one would has reached maturity stage. Now is the time for applying for PM award. Also think of challenging level to which you can take this movement. |

TQM | Homeopathy| GOLF| Cotact Us |

Copyright � 2013-17"pdponline"

Page designed, created and

maintained by pdpal.