|

|

|

|

GOLF |

|

||

The Seven

Basic Tools of Quality is a

designation given to a fixed set of graphical techniques identified as being

most helpful in troubleshooting issues related to quality. They

are called basic because they are suitable for people

with little formal training in statistics and because they can be used to solve

the vast majority of quality-related issues.

The seven tools are:

�

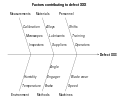

Cause-and-effect diagram (also known as the

"fishbone" or Ishikawa diagram)

�

�

Stratification (alternately, flow chart or run chart)

The designation arose in postwar Japan,

inspired by the seven famous weapons of Benkei. It

was possibly introduced by Kaoru Ishikawa who in turn was influenced by a series

of lectures W. Edwards

Deming had given to

Japanese engineers and scientists in 1950. At

that time, companies that had set about training their workforces in statistical

quality control found

that the complexity of the subject intimidated the vast majority of their

workers and scaled back training to focus primarily on simpler methods which

suffice for most quality-related issues.[8]

The Seven Basic Tools stand in contrast to more

advanced statistical methods such as survey sampling, acceptance sampling, statistical hypothesis testing, design of experiments, multivariate analysis, and various methods

developed in the field of operations research.

|

Cause-and-effect diagram |

|

Check sheet |

|

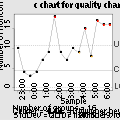

Control chart |

|

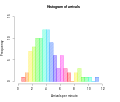

Histogram |

|

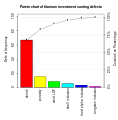

Pareto chart |

|

Scatter diagram |

|

Run chart |

he Seven

Management and Planning Tools have

their roots in Operations Research work done after World War II and the Japanese Total Quality Control (TQC) research.

In 1979 the book Seven New Quality Tools for

Managers and Staff was

published and was translated into English in 1983.

|

Affinity

diagrams are a special kind of brainstorming tool that organize large amounts of

disorganized data and information into groupings based on natural

relationships. It was created in the 1960s by the Japanese

anthropologist Jiro Kawakita. Its also known as KJ diagram,after Jiro

Kawakita.When to Use an Affinity Diagram 1)When you are confronted with many

facts or ideas in apparent chaos 2)When issues seem too large and complex to

grasp |

|

This tool displays all the interrelated cause-and-effect relationships and factors involved in a complex problem and describes desired outcomes. The process of creating an interrelationship digraph helps a group analyze the natural links between different aspects of a complex situation. |

|

This tool is used to break down broad

categories into finer and finer levels of detail. It can map levels of

details of tasks that are required to accomplish a goal or solution or task.

Developing the tree

diagram helps

one move their thinking from generalities to specifics.

|

|

This tool is used to prioritize items and describe them in terms of weighted criteria. It uses a combination of tree and matrix diagramming techniques to do a pair-wise evaluation of items and to narrow down options to the most desired or most effective. Popular applications for the Prioritization Matrix include Return-on-Investment (ROI) or Cost-Benefit analysis (Investment vs. Return), Time management Matrix (Urgency vs. Importance), etc. |

|

This tool shows the relationship between items. At each intersection a relationship is either absent or present. It then gives information about the relationship, such as its strength, the roles played by various individuals or measurements. Six differently shaped matrices are possible: L, T, Y, X, C, R and roof-shaped, depending on how many groups must be compared. |

|

A useful way of planning is to break down tasks into a hierarchy, using a tree diagram. The PDPC extends the tree diagram a couple of levels to identify risks and countermeasures for the bottom level tasks. Different shaped boxes are used to highlight risks and identify possible countermeasures (often shown as 'clouds' to indicate their uncertain nature). The PDPC is similar to the Failure Modes and Effects Analysis (FMEA) in that both identify risks, consequences of failure, and contingency actions; the FMEA also rates relative risk levels for each potential failure point. |

|

This tool is used to plan the appropriate sequence or schedule for a set of tasks and related subtasks. It is used when subtasks must occur in parallel. The diagram enables one to determine the critical path (longest sequence of tasks). (See also PERT diagram.) |